|

I recently had the opportunity to spend time with one of Sayoc Kali's senior instructors, Lakan Walo Guro

Ray Dionaldo. Ray is the manufacture of the Sayoc Tactical line of training blades. I was privileged to watch

the entire production process of the training blades that many of us use through out our training. Ray has spent several

years training with Tuhon Chris Sayoc, Grand Tuhon Bo Sayoc and was one of Professor Presas's primer students. Not only

has he spent years studying the tactical arts, he has also spent years studying knife making and actually making live blades.

This expertise in the making and use of the blade carries over into the making of the training blades.

The process begins, as many would expect, with an idea in mind. Ray spends several hours thinking about

what the training blades should look like, what function they will perform and how they will be used. Next, Ray builds a full

size prototype out of plastic. He then spends several hours, if not days, using the prototype in actual training. He refines

the shape and size until he is happy with the way it feels and performs. He also is extremely careful about balancing the

blade to be able to spin in the hand, something that we Sayoc Kali practitioners do all the time. If it does not meet his

expectations, its back to the drawing board and a new prototype is created. After he is satisfied with the plastic prototype

an actual Aluminum prototype is created, and several more hours are spent using the Aluminum prototype in training. Again,

refining the shape and feel until he is completely satisfied.

Now the actual production phase begins. This process is completely hand done. There are no magic boxes or

machined production lines to churn out thousands of blades; Ray crafts each one by hand. Ray starts with a special Aluminum

alloy and traces out the shape on the blank stock. Next the stock is cut down into a rough shape on a bandsaw and the edges

smoothed on a grinder and the holes drilled into the handles.

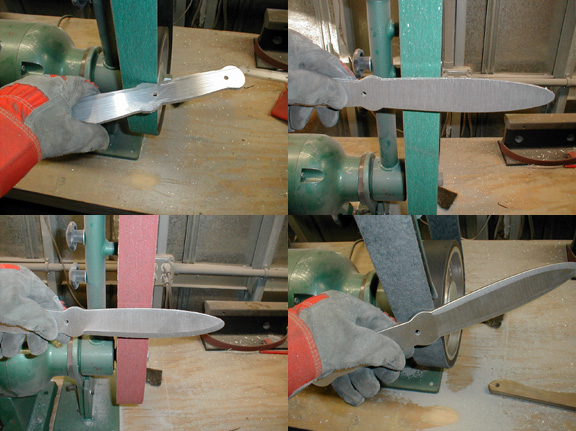

The next several steps require painstaking patience and precision as each step is hand done, with out the

use of special brackets or jigs. The flat sides of the training blades are smoothed out and polished on a belt sander. This

requires several steps as the belts are changed from the most course grit to the finest polishing belt. Next all of the sharp

square edges are beveled and the sides of the blade are smoothed out and polished. This process again takes several steps,

as Ray is a perfectionist. No sharp edge is left untouched. Even the punio is beveled and polished.

After the Aluminum Blade has been polished the final bevels are created to simulate the cutting edges of

a real blade. Keep in mind that each time a piece is polished it requires several steps, as the coarseness of the sanding

belt is reduced until the Aluminum is finally polished. Now it is time for the finishing touches. The plastic handle inserts

are cut into shape and all of the rough edges are removed and each handle is then hand wrapped using Ray's special technique.

It's easy to see why the quality of the Sayoc Tactical line of training blades is purchased worldwide. Ray

is one of the only suppliers of training blades to Europe and Australia, as most of their local blade manufactures have gone

out of business. Next time you pick up a training blade take the time to carefully look at it and appreciate the amount of

time and years of experience Ray imparts into each one of the training blades. Each training blade truly is a hand made piece

of art.

|